About Us

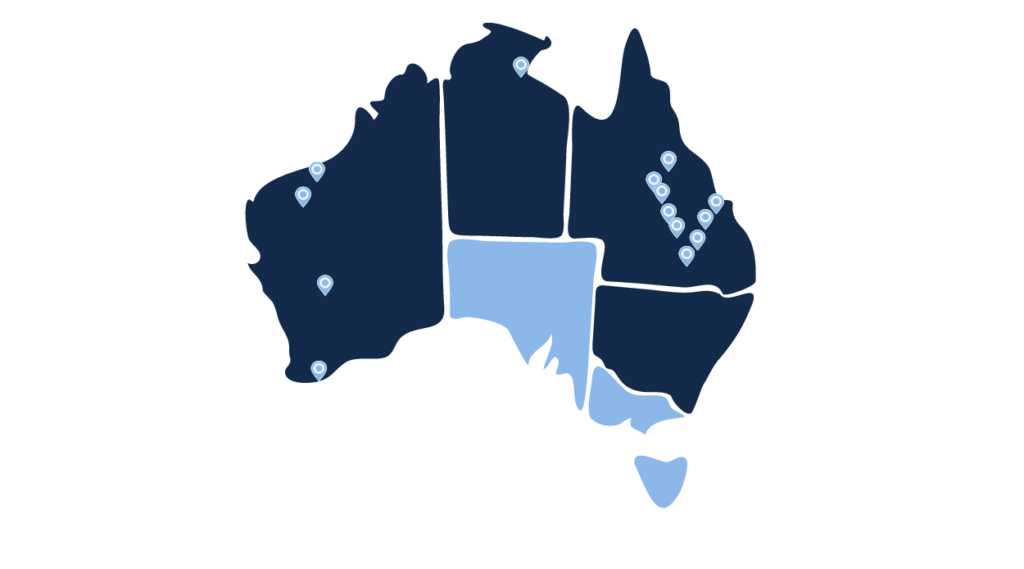

With one of the largest and most capable production drilling fleets in the country, which, together with our specialist engineering capability and extensive blasting experience, ADB delivers safe, efficient, fully integrated drill and blast solutions to our clients.

We have firmly established our reputation for delivering consistently high performance across the spectrum of commodities in Australia including coal, iron ore, lithium, gold and related civil works including rail and mine site establishment.

Our partnership approach, agility and innovation, coupled with an industry leading safety focus has resulted in an enviable proven performance record.